Description

The Provident Depanner is totally washdown IP69K. We have designed and built the next generation of inline depanner systems that will change the industry, forever. This video shows the latest innovation offered by our Provident Depanner.

Details

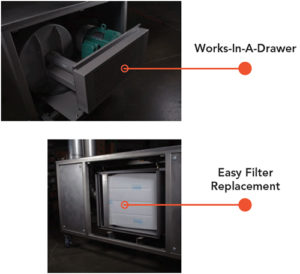

Welcome a giant leap in depanner technology, the Provident Series, offering a complete washdown system for the conveyor, depanner and vacuum chamber; JSD auto vacuum control; remote low profile vacuum module; and works-in-a-drawer vacuum blower/motor accessibility.

The Provident is built to meet:

- FDA, USDA and ANSI 50.2 standards!

- BRC Global Standard for Food Safety!

- Vacuum chamber and conveyor system IP69K Washdown rating!

No one else in the industry offers one.